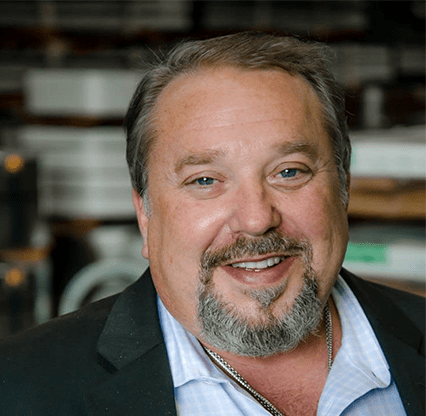

Rob Moeck | CEO & President | Bay Cities Metal Products

Rob Moeck

CEO & President

" The courage and freedom to discuss areas of improvement with management are critical to improving the customer experience. "

A Wholesome Leader

When Rob Moeck started at Bay Cities, there needed to be a management team in place. All departments were “siloed,” and no one was working together. In addition, the company had lost sight of the customer and was attempting to sell the way that the company wanted to sell, vice how the customer wanted to buy. The first thing Rob did was develop an inclusive culture of all voices in the organization. “We listened to the employee about changes we were making and asking for input. We listened to the customer about what we could do better. We have a tag line “Quality People, Quality Products,” and that is really what it comes down to,” says Rob. “In addition, we developed a culture that welcomes mistakes. It sounds odd, but, we want our teams to be able to say that a mistake occurred without fear of reprisal. Once we fix it, we are now right and doing things better. The courage and freedom to discuss areas of improvement with management are critical to improving the customer experience.”

Owing to his unique mindset, Rob has culminated into a support system for the budding entrepreneurs who are out there trying hard to establish themselves. When time allows, the CEO & President of Bay Cities Metal Products does consult for entrepreneurs. Rob’s focus is generally on building detailed plans with metrics and KPIs to help keep on track.

Another area he focuses on for new startups and existing organizations is the concept of the 20 Mile March. “Stay the course and do not overextend when it is easy and do not slack off when it is hard. For example, if you try and extend your geography of sales too quickly and you have not developed a strong operational system, you run the risk of stressing the entire organization,” advises Rob. “A further area to always consider is the customer experience. Knowing who your customer is, what they want, and how they want to interact with your company is key to keeping and growing a customer base.”

A Steadfast Chief

Rob’s path was not typical, and he has seen many leadership styles in his career. Rob could see some decisive leadership and inferior management styles from being in the Navy on a Nuclear Submarine. Hence, for Rob, focusing on the people is key to driving a supportive culture and making a workplace “a good place to work”. “I strive to make our jobs as fun as possible (work is work, but we try and do little things to improve it). Knowing who works for you, greeting them when you see them, listening to them and following through, honoring promises made to the employees and most important, be authentic,” explains Rob. “A simple example of how you can change culture. Our office did a monthly cake for all office employees who had a birthday that month. Someone from our shop floor joked that no one celebrated his birthday. So now, we celebrate everyone in the company who has a birthday that month. The name goes on a board, and we change the food item up. We have done cupcakes to Hawaiian Ice to churros. Everyone here is important, and we need to find new ways to make sure that they feel that way.”

Building A Brand

With his different outlook and being a true people leader, Rob has taken the company to new heights. Bay Cities is a leading sheet metal fabricator serving the homebuilding market in southern California for over 60 years. They design and manufacture sheet metal products used in roofing and guttering and sell exclusively through distribution. Their capabilities are vast, utilizing a 230,000 ft2 of manufacturing facility between three locations with 175 employees to design and build various standard and custom products.

The company is attempting to integrate AI into its systems to predict customers’ needs better both on a short-term basis and on a longer view to determine the right mix of raw and finished goods, depending on seasonality, the industry, and customer activity. It will strengthen inventory and allow for more skill in the market while increasing the customers’ ability to rely on us to have the parts when they need them.

Towards the Future

Bay Cities products are, for the most part, commodities. There are some quality differences between some parts and others, but for the most part, it would be hard to differentiate one product from another. Their solutions range in the “Customer Experience”—what each customer wants from us to make their job easier—from doing physical inventories for locations to seminars with the end users about the difference in metals and how they perform.

Specifically, Bay Cities had a large, multi-billion-dollar national customer who wanted them to expand geographically. He gave several reasons that would be advantageous for his company and himself. “We studied the needs that he presented, realized that others would benefit similarly as he did, and, after much work and discussion, raised funds for an acquisition,” elucidates Rob. “Now we have expanded our business with them and others just by listening to the needs of the customer.”

For Rob, one of the company’s most significant achievements has been taking a company that had no processes or procedures and was very siloed and increasing the EBITDA by 357% and the top-line revenue by 133%. To do this, Rob and his team had to rebuild each department from accounting to shipping and receiving and everything in between to prove to the customers that they could deliver the right part to the right location at the right time. “The rest is just being there and being who the customer needs. Building the team that could accomplish this with me was the most fun,” says Rob. “Mentoring, helping and guiding the team into being the leaders in our industry and being recognized by others as world-class is something I am very proud of.” For the days to come, Rob has his eyes set on transforming the company and implementing a system that will make work easier for those in the company.